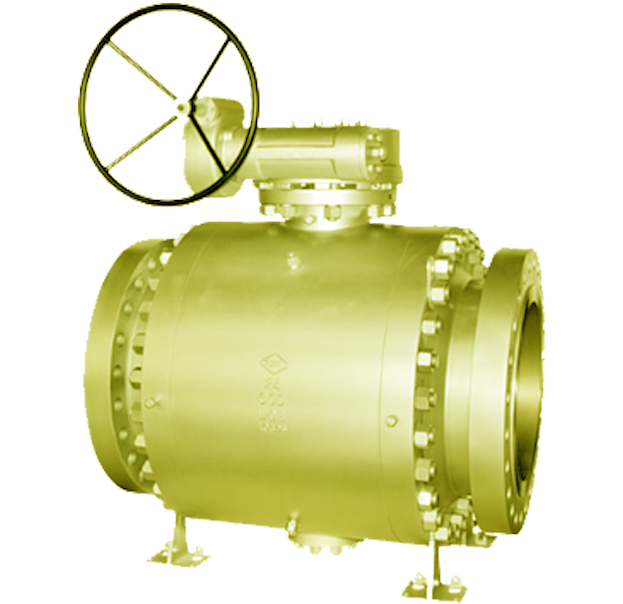

Trunnion Ball Valve - Flanged Class 600

Typical specs

-

Type: Trunnion-mounted floating ball with fixed trunnion bearings

-

Body materials: Carbon steel (A216 WCB), stainless (CF8M), low-temperature steels or alloys

-

The BIAV-TBVWV-670 model of Trunnion Ball Valve has the following ball/seat materials: 316/17-4PH or alloyed options; seats PTFE, RTFE, metal seat for high temp

-

Pressure class: ANSI Class 600 (rated up to ~1440 psi at low temps — verify spec chart)

-

Ends: Flanged RF or RTJ (ring-type joint)

-

Sizes: typically 2"–48" available; large sizes upon request

-

Features: Double block & bleed, fire-safe design, anti-static, stem blowout proof

-

Actuation: Gear operator / pneumatic / electric / hydraulic

Trunnion Ball Valve - Flanged Class 600

The Trunnion Ball Valve – Flanged Class 600 (BIAV-TBVWV-670) is designed for high-pressure, high-temperature pipeline applications. Its trunnion-mounted ball design ensures reduced operating torque and stable sealing under ANSI Class 600 ratings, providing secure isolation in oil, gas, and petrochemical industries.

Engineered with fire-safe, anti-static, and blowout-proof features, the Trunnion Ball Valve (BIAV-TBVWV-670) ensures compliance with API and ASME standards. Available with gear, pneumatic, or electric actuation, it delivers reliability, safety, and long-lasting performance in demanding industrial operations.

Selection checklist

-

Confirm system operating pressure & temperature against Class 600 rating (use flange pressure-temperature charts).

-

Choose material of construction for H₂S, sour service, or high-temp.

-

Is DBB (double block and bleed) required? If yes, specify.

Maintenance & commissioning

-

Hydrostatic test per API 6D or ASME B16.34 as required.

-

Torque verification on flange bolts to ensure seat sealing.

-

For optimal productivity, the BIAV-TBVWV-670 Trunnion Ball Valve requires periodic seat inspection; lubricate/bleed packing per manufacturer.