Canned Motor Vacuum Blowers

Typical specs

-

Type: Canned (hermetically sealed) motor-integrated blower/compressor; no shaft seal

-

Application: handling process gases, vacuum, or corrosive media with zero external leakage

-

Flow & vacuum: medium to high vacuum depending on design

-

Materials: wetted parts selectable for corrosive gases (SS316, special alloys)

Applications

-

Pharmaceutical processing, semiconductor tools, chemical plants where leakage is unacceptable

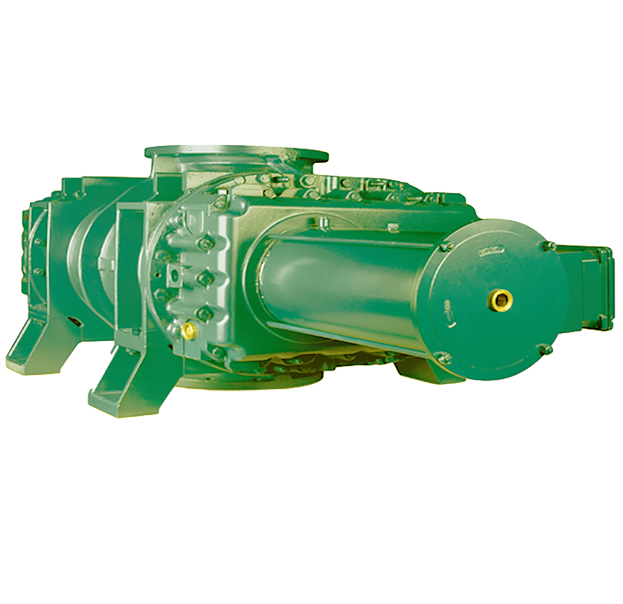

Canned Motor Vacuum Blowers

The Canned Motor Vacuum Blower (BIAB-CMVB-309) integrates a motor and blower in a sealed, leak-proof design. With no shaft seal, it eliminates the risk of leakage, making it suitable for hazardous or sensitive environments.

Ideal for chemical, pharmaceutical, and high-purity industries, the Vacuum Blower (BIAB-CMVB-309) ensures oil-free, contaminant-free vacuum generation. Its robust construction, quiet operation, and long service intervals make it a reliable choice for continuous, critical operations.

Selection checklist

-

Confirm gas composition and whether materials are compatible.

-

Confirm that canned motor’s cooling method is adequate for gas properties.

-

Check serviceability and repair options (often replaced as modules).

Maintenance & commissioning

-

Ensure appropriate inlet/outlet instrumentation (vacuum gauges, relief valves).

-

Monitor motor temperature and vibration.

-

Follow OEM guidance for run-up and shut-down to avoid thermal shocks.