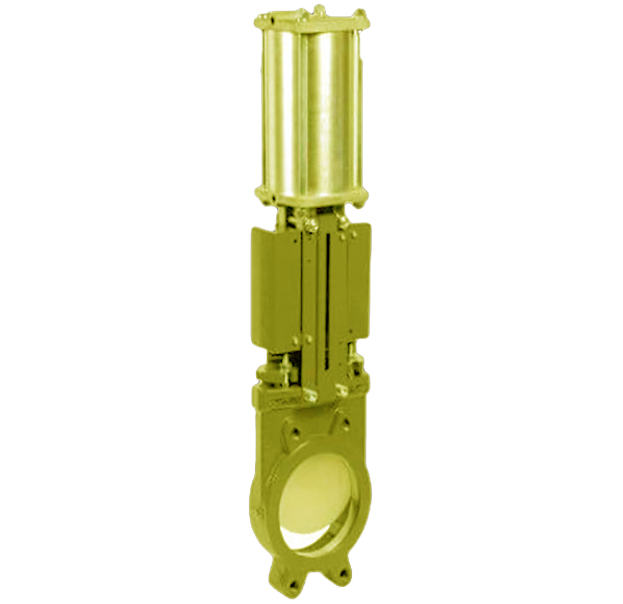

Pneumatic Actuated Knife Gate Valve

Typical specs

-

Body: Cast iron, ductile iron, carbon steel or stainless steel (316L)

-

Gate: Stainless steel or coated carbon steel for abrasion resistance

-

Seat: Resilient rubber (for sealing) or metal-seat for high-temp/abrasion

-

Actuator: Pneumatic cylinder (single-acting spring return or double-acting)

-

Sizes: 2"–72" (large-bore capability)

-

Pressure rating: Low to medium (depends on seat design), typical differential up to ~150 psi on resilient designs; metal-seat versions handle higher differentials

-

Sealing: packing gland or inflatable seals (for slurries)

-

Standards: ISO 5211 mounting for actuators; API or EN equivalents for design checks

Pneumatic Actuated Knife Gate Valve

The Pneumatic Actuated Knife Gate Valve (BIAV-PAKGV-436) is engineered for handling slurries, viscous fluids, and bulk solids in demanding industrial environments. Its sharp-edged gate cuts through media, ensuring reliable shutoff even in abrasive or clog-prone pipelines. Actuation is automated by pneumatic cylinders, providing rapid and consistent operation.

With stainless steel or ductile iron construction, the Pneumatic Knife Gate Valve (BIAV-PAKGV-436) ensures durability against corrosion and wear. Its design minimizes downtime by allowing easy maintenance and seal replacement. Suitable for mining, wastewater, pulp & paper, and chemical processing, this valve offers efficiency, precision, and reliability in critical flow systems.

Selection checklist

Is it a slurry/solid-laden flow? -> choose wider clearances and replaceable gate faces

Are inflatable seals required for high tightness?

Are valve face materials and coatings compatible with slurry abrasiveness?

Actuation air supply & lubricator/regulator requirements

Maintenance & commissioning

-

Ensure pneumatic actuator pressure and stroke adjustment are correctly set.

-

Inspect gate face and seat for wear; replace packing or seals regularly.

-

Confirm actuator lubrication schedule and air supply filtration.