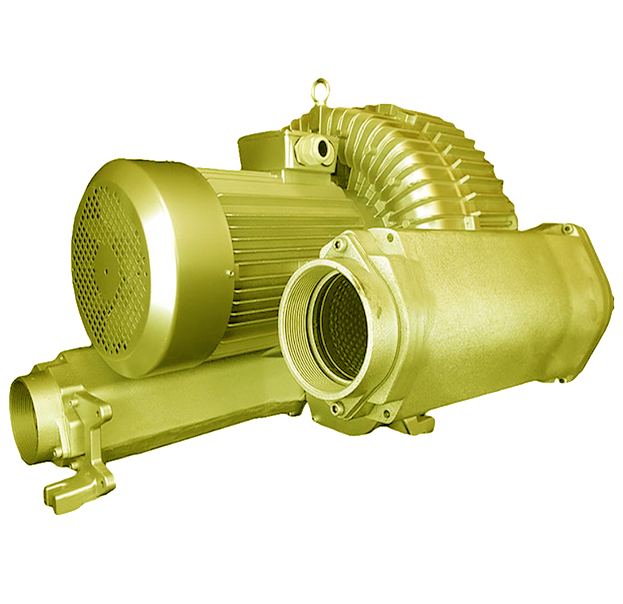

Regenerative Blower (3-phase 230/460 VAC)

Typical specs

-

Motor: 3-phase, 230/460 VAC (select motor voltage per local supply)

-

Type: Regenerative (side-channel) blower — oil-free air delivery

-

Flow: often 50–1000+ m³/hr depending on frame size

-

Pressure/vacuum: moderate positive pressure or vacuum capability (often up to ~65–80 kPa differential depending on size)

-

Features: low maintenance, low vibration, compact, thermally protected motors

Applications

-

Air knives, packaging, vacuum pickup, small pneumatic conveying where oil-free air is required

Regenerative Blower (3-phase 230/460 VAC)

The Regenerative Blower (3-Phase 230/460VAC) - BIAB-TPRB-365 provides oil-free, non-pulsating air suitable for clean industrial applications. Powered by a three-phase motor, it offers high reliability, low maintenance, and extended service life.

Commonly used in packaging, pneumatic conveying, and medical equipment, the Regenerative Blower (BIAB-TPRB-365) ensures consistent performance with minimal noise and vibration. Its compact design, combined with high efficiency, makes it ideal for installations requiring continuous, maintenance-free operation.

Selection checklist

-

Confirm motor supply and starter requirements (star/delta, VFD, etc.)

-

Is continuous duty needed? Check motor cooling at required operating point.

-

Check permissible inlet temperature and altitude derating.

Maintenance & commissioning

-

Check motor wiring for 230/460 configuration and install thermal protection.

-

Install inlet filter and silencer.

-

Periodic bearing checks; most are near maintenance-free but monitor temps.