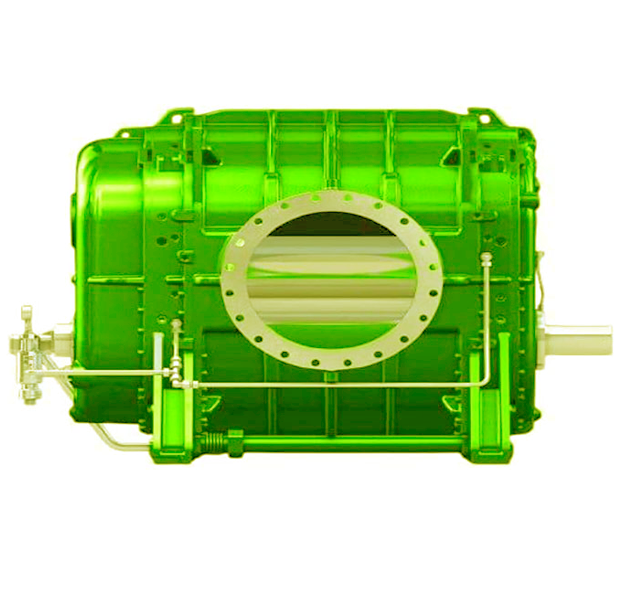

Positive Master Displacement Blower

Typical specs

Type: Roots-style or tri-lobe positive displacement blower (sometimes marketed as Positive Master)

Flow: wide range (30–20,000 m³/hr) depending on frame size

Pressure: typically up to ~1 bar differential (check OEM curves)

Features: robust, steady flow independent of downstream pressure (within limits)

Applications

- This model (SZAB-PMDB-945) applies to pneumatic conveying, wastewater aeration, industrial processes requiring constant volume

Positive Master Displacement Blower

The Positive Master Displacement Blower (SZAB-PMDB-945) is a heavy-duty, positive-displacement blower engineered to deliver steady, pulsation-free airflow for continuous duty. Built for reliability, it provides consistent volumetric flow across variable back-pressures, making it ideal for pneumatic conveying, wastewater aeration, and process air applications.

Designed for demanding environments, the SZAB-PMDB-945 offers optional corrosion-resistant finishes and flexible drive arrangements. Routine maintenance is straightforward, ensuring efficient long-term performance and cost-effective operation in critical airflow systems.

Selection checklist

Determine required volumetric flow at specific pressure (use blower performance curves).

Confirm need for lubrication (gearbox and timing) and whether oil-free air is needed.

Provide bypass/relief valves and cooling if operating at high differential pressures with SZAB-PMDB-945 model.

Maintenance & commissioning

Regular gearbox oil checks; monitor for overheating.

Timing and rotor clearance checks per OEM schedule.

Install vibration isolation and inlet/outlet filtration.